Replacing a VTOL Propeller

A VTOL propeller blade may need to be replaced if it is chipped, cracked, or damaged in any way. A damaged blade will cause a buffeting noise and high vibration. A vibration warning may be triggered in flight depending on the extent of damage.

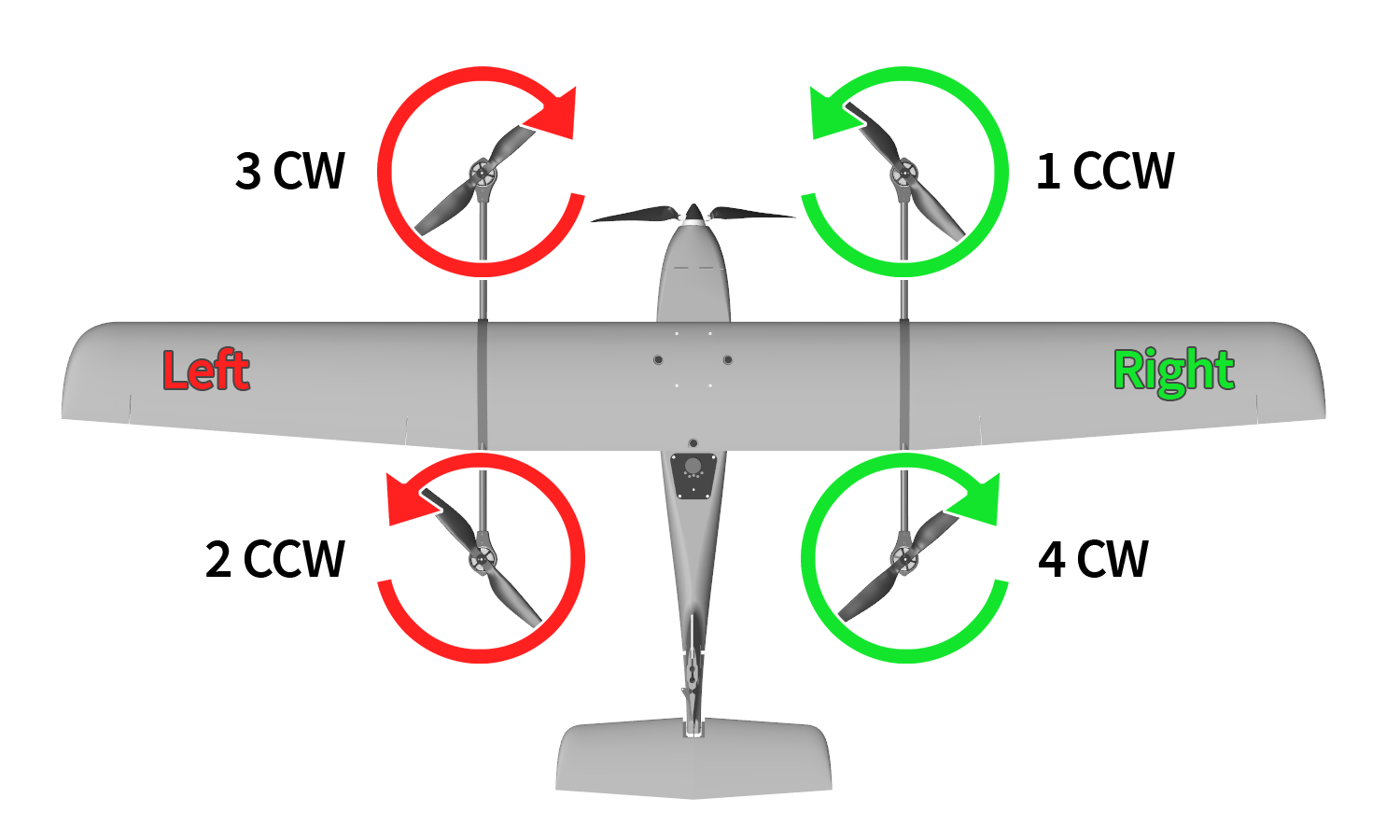

Lynx VTOL has four vertical lift motors. Each motor is numbered. The motor number corresponds to the direction the propeller spins, clockwise or counter clockwise. The motor and spin directions are physically labelled on each motor boom.

Lynx VTOL uses a T-Motor 15x5 carbon fiber propeller for the VTOL propellers.

Tools Needed: 2.5 mm hex key, blue thread locker (medium strength)

To replace a propeller:

Disconnect the batteries from the aircraft.

Note the propeller orientation and find a matching one. The VTOL propellers can be either clockwise (CW) or counter clockwise (CCW) rotation. The propellers have a label on them that indicates the rotation direction. Use the table below to select the correct propeller.

| Label | Direction | Motor |

|---|---|---|

| 15x5L | CW | 3, 4 |

| 15x5R | CCW | 1, 2 |

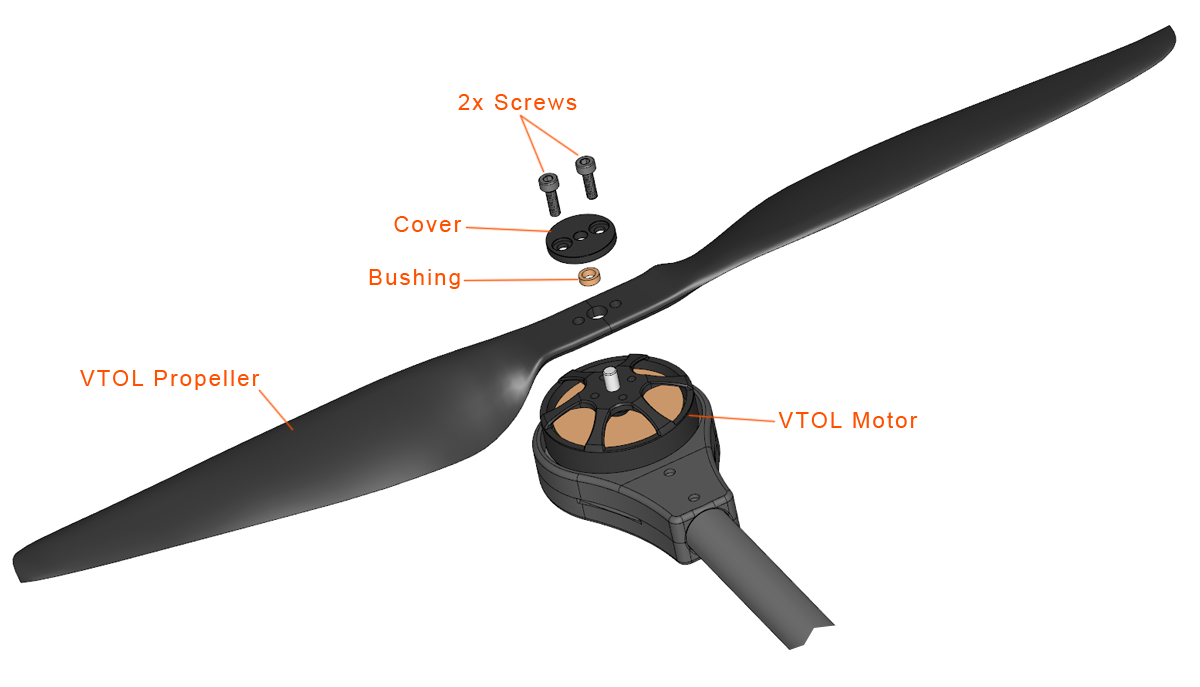

Remove the two screws holding the propeller to the motor.

Discard the damaged propeller, but keep the two screws, cover, and copper bushing. The bushing may be stuck in the propeller and therefore needs to be pushed out.

Insert the bushing around the motor shaft and place the new propeller around the bushing. Ensure you have the correct propeller and that it faces the correct way.

Caution: Always install the propeller with the logo and text facing up.

Reinstall the propeller with the same two screws and cover. Apply a drop of thread locker to each screw and loosely tighten each. With both screws in place, tighten them down finger tight.

Warning: Installing the wrong propeller or installing a propeller on backwards will cause extremely high vibration and will not effectively product thrust. This may damage the motor, motor mount, and/or aircraft. A backwards VTOL propeller will cause the aircraft to tip over on takeoff.